albion zinc bisglycinate

In the field of pharmaceutical preparations, a coating tablet is a tablet form that has undergone special processing. Its core is a core composed of active ingredients of the drug, and the outer layer is wrapped with a uniform and dense coating film. This seemingly simple outer layer endows tablets with many excellent characteristics through scientific design, becoming an important way to improve drug quality and efficacy. The structure of the Coating Tablet is clearly hierarchical from the inside out The innermost layer is the tablet core, which is made by mixing and pressing the active ingredients of the drug with excipients. The excipients usually include fillers, adhesives, and disintegrants, ensuring accurate drug dosage and providing a stable base for subsequent coating. The middle layer is an isolation layer, often made of materials such as hydroxypropyl methylcellulose, which can prevent chemical reactions between the core components and the coating material, while reducing water infiltration. The outermost layer is the functional coating layer, which can be divided into sugar coating, film coating, or enteric coating according to requirements. The thickness is usually only tens to hundreds of microns, but it determines the core characteristics of coated medicine tablets . The functional advantages of the Coating Tablet are reflected in multiple aspects Firstly, it is to mask the odor of drugs. Many drugs themselves have a bitter or irritating odor, and the coating film can effectively isolate the contact between drugs and taste buds, improving patients' medication compliance. Secondly, it is important to protect the drug components. The coating layer can block the effects of light, oxygen, and moisture on the tablet core, delay drug oxidation and degradation, and extend the shelf life. For enteric coating in tablets , its special design ensures that the drug does not dissolve in the stomach and is released only after reaching the intestine, avoiding irritation to the gastric mucosa while ensuring full effectiveness at the absorption site. The production process of Coating Tablets requires extremely high precision in the manufacturing process The coating material needs to undergo strict screening to ensure purity and stability; The parameters of the coating pan such as rotating speed, air inlet temperature and spray speed need to be precisely controlled to ensure uniform coating film. During the coating process, each drug needs to go through multiple spray and drying cycles to gradually deposit the coating material to form a complete film. Any parameter deviation may lead to uneven coating, cracking or peeling, affecting product quality. Coating tablets are widely used in the pharmaceutical industry Compressed coated tablets are widely used in the pharmaceutical industry, ranging from common cold medicines and painkillers to complex sustained-release formulations. For example, the use of coating technology for certain antibiotics can reduce irritation to the gastrointestinal tract; Extended release coating tablets can slow down the release of drugs in the body, prolong the duration of action, and reduce the frequency of medication; Enteric coated enteric tablets provide a safer medication option for patients with gastric sensitivity. In summary, continuous tablet coating , through scientific structural design and precise production processes, endows tablets with multiple functions such as masking odors, protecting ingredients, and controlling release, playing a key role in improving drug stability, safety, and patient compliance. As a mature form of drug formulation, it not only meets the diverse needs of clinical treatment, but also reflects the ultimate pursuit of details in pharmaceutical technology, providing important support for the development of the pharmaceutical field. Coating Tablet FAQs What is a Coating Tablet? A coating tablet refers to a dosage form that covers the surface of a regular tablet with a layer of high molecular weight polymer film. This layer of film is usually composed of film-forming materials, plasticizers, coloring agents, and other components, which are uniformly attached to the surface of the core through coating technology. Compared with traditional sugar coated tablets, Coating Tablets have the characteristics of being thinner and more uniform, which can improve the stability of drugs, mask unpleasant flavors, and achieve specific release effects. What are the advantages of a Coating Tablet? The main advantages of coating tablets include improving drug stability and preventing damage to active ingredients from light, moisture, or oxygen. Its smooth surface is easy to swallow and can mask the bitterness or odor of drugs. Some coating materials can also achieve enteric or sustained-release functions, accurately controlling the position and time of drug release. In addition, the coating tablet process takes less time and is more suitable for industrial production. What are the typical materials for a Coating Tablet? Common coating tablet materials are divided into three categories: water-soluble (such as hydroxypropyl methylcellulose), gastric soluble (such as polyvinyl alcohol), and enteric soluble (such as cellulose acetate phthalate). Plasticizers such as polyethylene glycol can enhance the flexibility of thin films, while light blocking agents such as titanium dioxide can protect photosensitive components. Modern coating materials also focus on the development of allergen free, sugar free, or plant-based formulas. What are the key steps in the coating tablet process? Coating Tablet process mainly includes four stages: core pretreatment, coating solution preparation, spray coating and drying. The core of the tablet needs to have sufficient hardness and smoothness to withstand the coating process. The coating solution needs to be evenly dispersed and its viscosity controlled. In the spray stage, the atomized droplets are evenly covered with the core through the fluidized bed or coating pan, and the film is dried and solidified by hot air. Technological parameters such as temperature, wind speed and spray rate directly affect the coating quality. How to evaluate the quality of Coating Tablets? Quality assessment covers indicators such as appearance (uniform color, no cracks), weight gain ratio (proportion of coating layer weight), solubility (whether it meets release requirements), and mechanical strength (wear resistance). Modern detection techniques such as near-infrared spectroscopy can monitor coating thickness in real-time, while in vitro disintegration tests and in vivo bioequivalence studies validate its functionality. Stability testing requires simulating long-term storage conditions to ensure performance within the validity period.

Finutra devotes to be an integrated supplier for global supply chain, we offer a

broad array of raw materials and functional ingredients

Authoritative Certification

Continuous Innovation, Customer First

Enhance core competitiveness to bring customers better products and services,

Each of these is the result of our team's relentless pursuit of excellence

and our deep commitment to social responsibility.

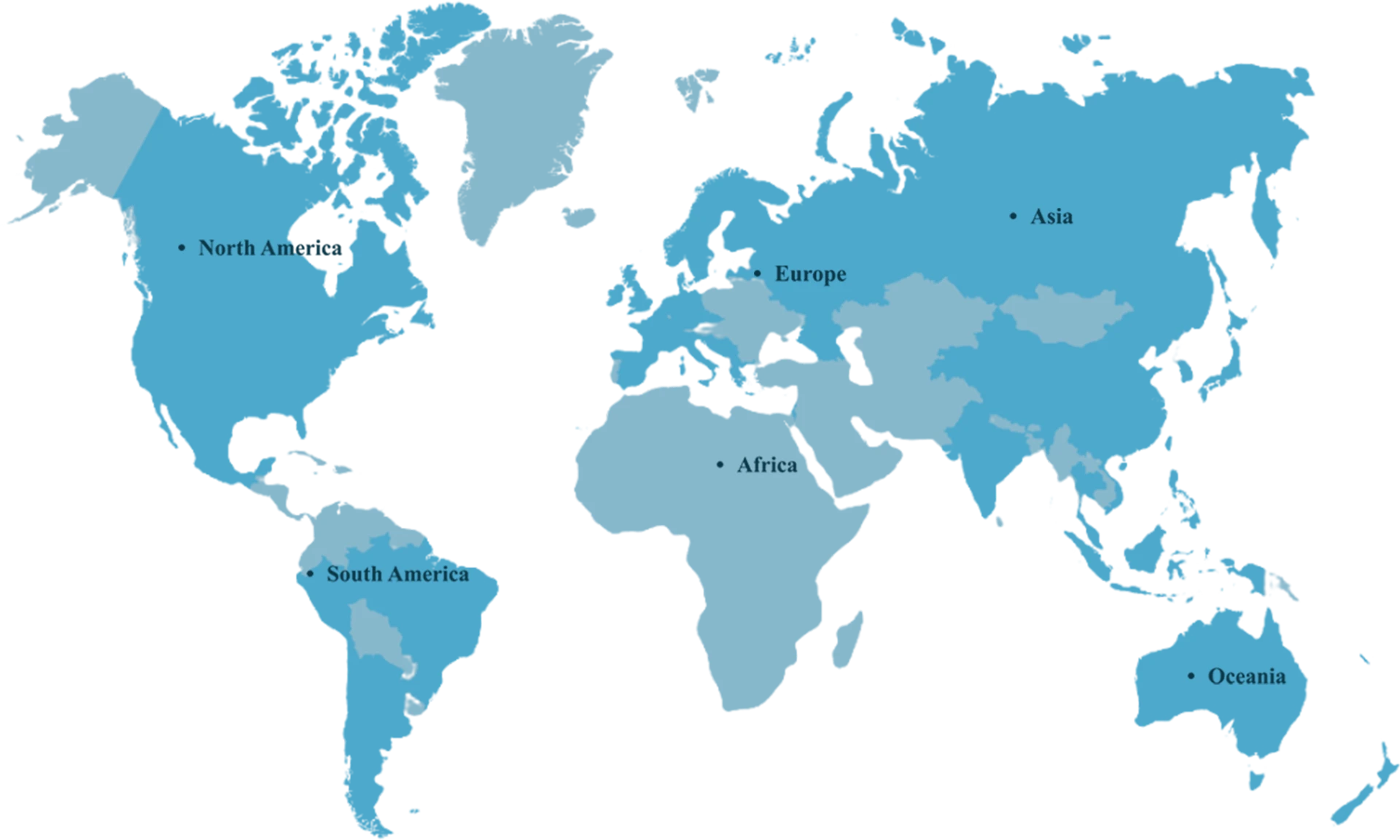

Global

Reach

FINUTRA has over 350,000 square feet of manufacturing and warehouse

space worldwide.

Industries We Serve

Advanced molecular distillation and microencapsulation

technology. Extremely bioavailable

trace carotenoids Intuitively soluble.

STAY UPDATED

Receive special offers and first look at new

products.

products.

Building 23B1, No.2 Yuanboyuan St., Zhengding Area of China (Hebei) Pilot Free Trade Zone

QUICK LINK

Finutra devotes to be an integrated supplier for global supply chain, we offer a broad array of raw

materials and functional ingredients as a manufacturer, distributor and supplier for global Beverage,

Nutraceutical, Food, Feed and Cosmeceutical.

Copyright © 2025 Hebei Finutra

Biotech Co.,

Ltd. All

Rights Reserved.

Privacy Policy